Stabilizing the mechanical parts to get smoother prints

The pure G2S delta kit has a weak mechanical stability. Mechanical stability is however essential to get smooth, high quality 3D prints.

So in order to get out a good 3D print quality the mechanics had to be stabilized:

- I mounted some acrylic plates in front of the delta towers on all three sides. This reduced dramatically the mechanical weakness of the whole system. This is for my opinion the most important mechanical modification.

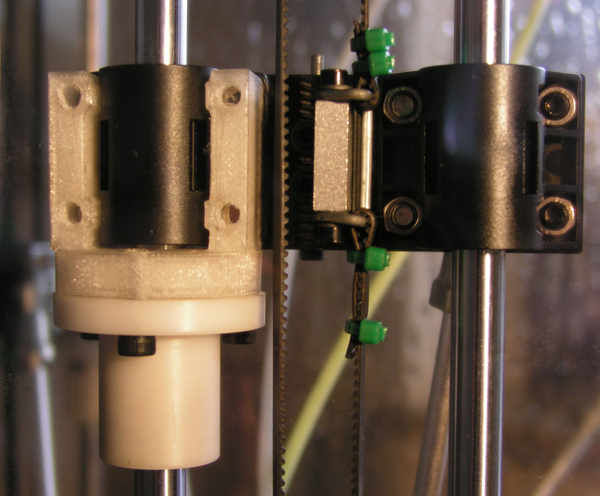

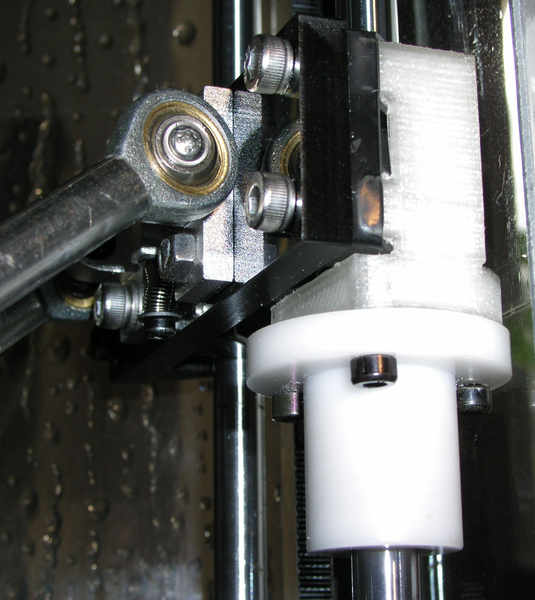

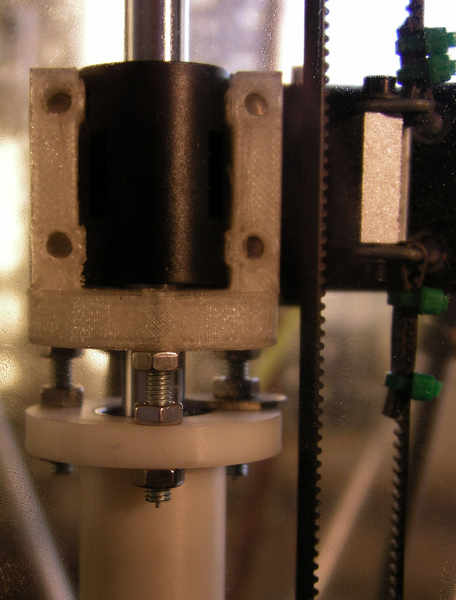

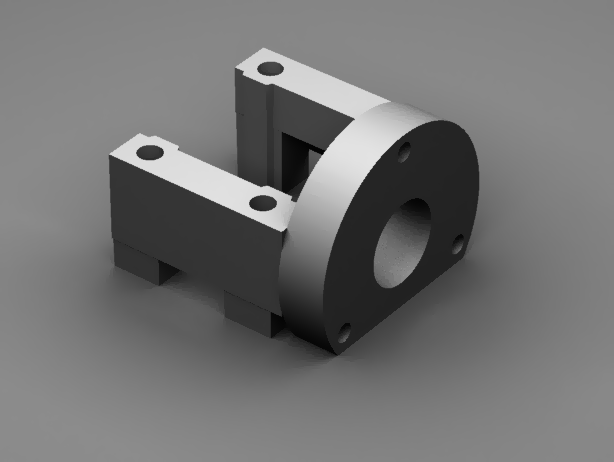

The mounting brackets for the acrylic plates are available for download as a STL file. - The guides for the smooth rods are very short. though they have low tolerances, they wobble because of that. So I decided to add a third linear bearing. that reduced the ability of the guide block to wobble. The 3D printed parts for that can be downloaded as a 3D stl file. Because I noticed that I could not tigthen all three screws for the lower bearing holder because of mechanical inacurracies that caused hard going bearings, I modified the lower bearing mounting using thread bolts. The thread bolts allow to adjust the parallelity of the upper and lower bearing very exactly. This is achieved by adjusting the nuts carefully. (See image 4 further down)

- Belt mounting. The proposed belt mounting from Geeetech to punch a hole into the belt and fix it with a screw, is somehow bad design and definitely a weak point were the belt probably may rip. So I bent a small wire clamp to mount the belts to using cable ties. The wire is also available as a stl file, though it makes no sense to print that, because it would not be stable enough.

The 3d stl files to create the parts may be downloaded here: